Umkhiqizi ohlakaniphile wezinto ezishisayo ezishisayo

Isipiliyoni Sokukhiqiza Seminyaka Engu-10+

- tiger.lei@jojun.net

- +86 512-50132776

I-JOJUN-6700 Series Thermal Pad

★ Izakhiwo Ezijwayelekile Ze-Jojun-6700 Series Thermal Pad

| Izakhiwo Ezijwayelekile Ze-JOJUN6700 | |||

| Impahla | Iyunithi | Uchungechunge Lomkhiqizo | Indlela Yokuhlola |

| JOJUN6700 | |||

| Umbala |

| Ngokwezifiso | Okubonakalayo |

| Ubukhulu | mm | 0.5-5 | I-ASTM D374 |

| SpecificAmandla adonsela phansi | g/cc | 3.1 | I-ASTM D792 |

| Ukuqina | Shore oo | 20-70 | I-ASTM D2240 |

| IsiceloIzinga lokushisa | ℃ | -50 - +200 |

|

| UkuvuthaIkilasi |

| V0 | UL94 |

| OkushisayoI-Conductivity | W/mK | 7 | I-ASTM D5470 |

| UkuhlukanaAmandla kagesi | KV/mm | >6 | I-ASTM D149 |

| IvolumuUkungazweli | ohm-cm | 10 ^14 | I-ASTM D257 |

| I-DielectricNjalo | 1MHz | 7 | I-ASTM D150 |

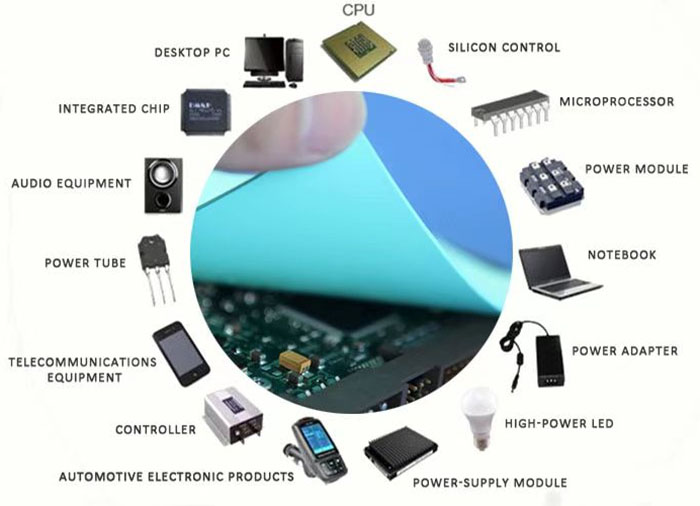

★ Isicelo

CPU

Izingxenye zokupholisa ku-chassis yohlaka

Amadrayivu esitoreji esikhulu esinesivinini esikhulu

Ukuzulazula kwe-GPS nezinye izisetshenziswa eziphathwayo

I-TV ye-LED nezibani ezikhanyiswe nge-LED

Amamojula wememori we-RDRAM

Izixazululo ezishisayo zamapayipi okushisa amancane

Izixazululo ezishisayo zamapayipi okushisa

Ihadiwe yokuxhumana ngocingo

Izinto zikagesi eziphathwayo eziphathwayo

Imishini yokuhlola ezenzakalelayo ye-Semiconductor (ATE)

★ Inqubo Yokukhiqiza

Hlanganisa Gxuma

I-Extrusion

I-Thermal Pad Production Line

Nqampuna

Iphakheji

Izimpahla Eziphumayo

★Isikhungo se-R&D

I-Voltage Breakdown Tester

I-Thermal Conductivity Tester

I-Kneader

Ilabhorethri

★Izici Nezinzuzo

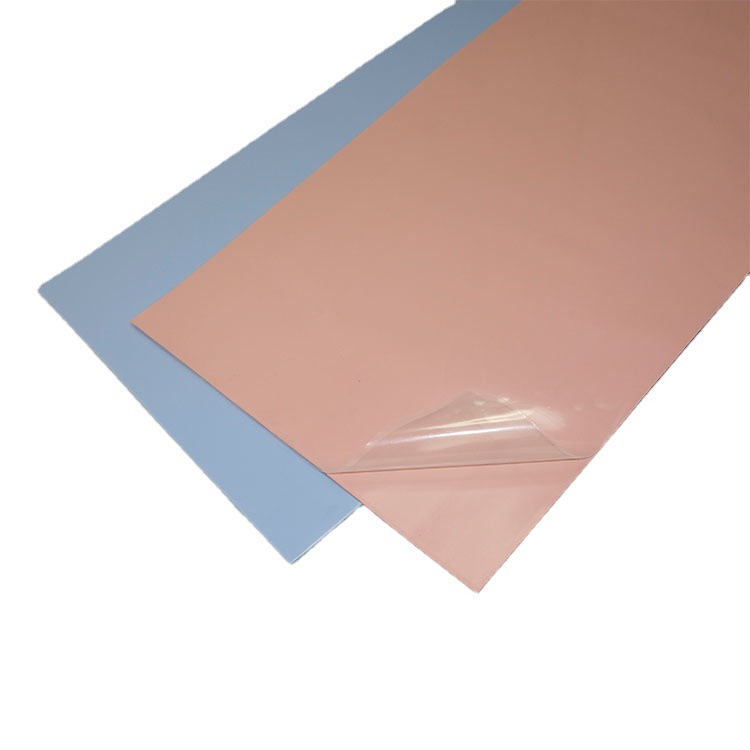

1.Nge-thermal conductivity engu-5.0 W/mK, i-JOJUN-6700 Series Thermal Pad ilungele izinhlelo zokusebenza lapho ukuqhutshwa kokushisa kuwukukhathazeka okubalulekile.Ukwengeza, iphedi i-tacky ngokwemvelo, ngakho-ke asikho isidingo se-adhesive coating eyengeziwe.Uzokwazi ukonga isikhathi nemali ngalo mkhiqizo omusha.

2.I-JOJUN-6700 Series Thermal Pad iyatholakala ngohlu olubanzi ukuze ivumelane nezidingo zakho zohlelo lokusebenza.Noma ngabe usebenza kuphrojekthi enkulu noma encane, uqinisekile ukuthi uzothola ukushuba okuphelele kwezidingo zakho.

3.Esinye sezici ezihlaba umxhwele kakhulu ze-JOJUN-6700 Series Thermal Pad ukwakhiwa kwayo okulula.Iphedi kulula ukuyifaka, futhi ngeke inamathele endaweni oyifaka kuyo.Lokhu kwenza kube nomoya ohelezayo ukubeka kabusha noma ukususa iphedi uma kudingeka.

★ Izitifiketi

Izici Zemikhiqizo Eshisayo

-

Izici ze-Thermal Pad

1. I-conductivity enhle yokushisa: 1-15 W / mK.

2. Ubulukhuni obuphansi: Ubunzima busukela ku-Shoer00 10~80.

3. I-insulating kagesi.

4. Kulula ukuhlanganisa. -

Izici ze-Thermal Paste

1. Isigcwalisi segebe esihlukanisekayo esinezingxenye ezimbili, ingcina ewuketshezi.

2. I-Thermal conductivity: 1.2 ~ 4.0 W/mK

3. Ukufakwa kwamandla kagesi aphezulu, ukucindezela okuphezulu, ukumelana nokushisa okuhle.

4. Isicelo sokucindezelwa, singafinyelela ukusebenza okuzenzakalelayo. -

Izici ze-Thermal Grease

1. Ukuhlukaniswa kwamafutha aphansi (kubheke ku-0).

2. Uhlobo oluhlala isikhathi eside, ukwethembeka okuhle.

3. Ukumelana nesimo sezulu esinamandla (ukumelana nokushisa okuphezulu nokuphansi -40 ~ 150 ℃).

4. Ukumelana nomswakama, ukumelana ne-ozone, ukumelana nokuguga.