Umkhiqizi ohlakaniphile wezinto ezishisayo ezishisayo

Isipiliyoni Sokukhiqiza Seminyaka Engu-10+

- tiger.lei@jojun.net

- +86 512-50132776

I-JOJUN-6100 Series Thermal Pad

★ Izakhiwo Ezijwayelekile ze-JOJUN-6100 Series Thermal Pad

| Izakhiwo Ezijwayelekile Ze-JOJUN6100 | |||

| Impahla | Iyunithi | Uchungechunge Lomkhiqizo | Indlela Yokuhlola |

| JOJUN6100 | |||

| Umbala |

| Ngokwezifiso | Okubonakalayo |

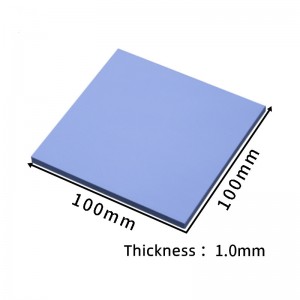

| Ubukhulu | mm | 0.5-5 | I-ASTM D374 |

| SpecificAmandla adonsela phansi | g/cc | 2.8 | I-ASTM D792 |

| Ukuqina | Shore oo | 30-70 | I-ASTM D2240 |

| IsiceloIzinga lokushisa | ℃ | -50 - +200 |

|

| UkuvuthaIkilasi |

| V0 | UL94 |

| OkushisayoI-Conductivity | W/mK | 1 | I-ASTM D5470 |

| UkuhlukanaAmandla kagesi | KV/mm | >6 | I-ASTM D149 |

| IvolumuUkungazweli | ohm-cm | 10 ^14 | I-ASTM D257 |

| I-DielectricNjalo | 1MHz | 7 | I-ASTM D150 |

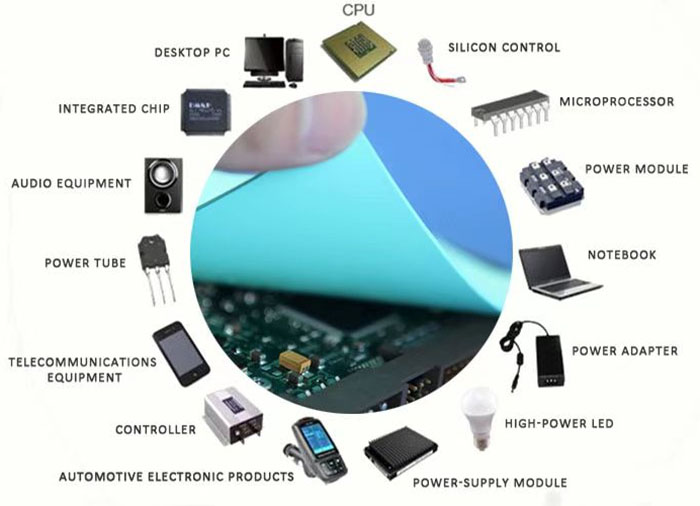

★ Isicelo

1. Imboni ye-LED

I-thermal conductive gasket isetshenziswa phakathi kwe-aluminium substrate kanye nosinki wokushisa.

I-thermal conductive gasket isetshenziswa phakathi kwe-aluminium substrate negobolondo.

2. Imboni yamandla

Sebenzisa i-heat conduction phakathi kweshubhu ye-MOS, i-transformer (noma i-capacitor/PFC inductor) kanye nesinki lokushisa noma indlu.

3. Imboni yezokuxhumana

I-Thermal conduction kanye nokukhishwa kokushisa phakathi kwebhodi elikhulu le-IC kanye nesinki sokushisa noma igobolondo.

Ukwenziwa kokushisa nokukhishwa kokushisa phakathi kwebhokisi elibekwe phezulu i-DC-DC IC negobolondo.

4. Imboni Yezogesi Zezimoto

Ama-thermal conductive gaskets angasetshenziswa ezinhlelweni zemboni yezimoto (njengama-xenon lamp ballasts, ama-stereo, imikhiqizo yochungechunge lwezimoto, njll.).

5. I-PDP/LED TV

Ukwenziwa kokushisa phakathi kwe-IC yesikhulisamandla samandla, isikhiphi sesithombe esingu-IC nesinki wokushisa (indlu).

★ Inqubo Yokukhiqiza

Hlanganisa Gxuma

I-Extrusion

I-Thermal Pad Production Line

Nqampuna

Iphakheji

Izimpahla Eziphumayo

★Isikhungo se-R&D

I-Voltage Breakdown Tester

I-Thermal Conductivity Tester

I-Kneader

Ilabhorethri

★ Ulwazi Lwesayensi Oludumile

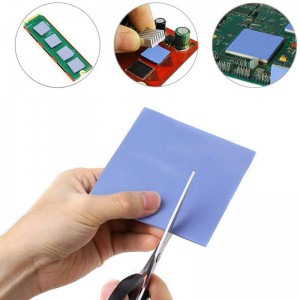

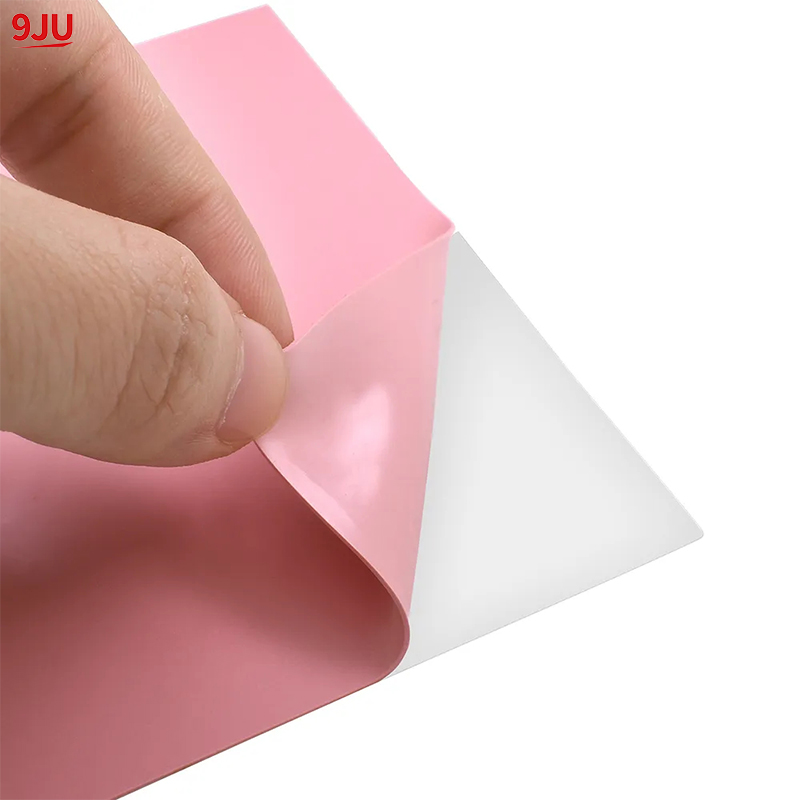

I-thermal conductive gaskets isetshenziselwa ukugcwalisa igebe lomoya phakathi kwensiza yokushisa kanye nesinki lokushisa noma isisekelo sensimbi.Izici zabo eziguquguqukayo nezinwebekayo zibenza bakwazi ukumboza izindawo ezingalingani kakhulu.Ukushisa kudluliselwa kusuka kudivayisi yokuhlukanisa noma i-PCB yonke kuya kugobolondo lensimbi noma ipuleti lokusabalalisa, elingathuthukisa ukusebenza kahle nempilo yesevisi yezingxenye ze-elekthronikhi zokushisisa.Iphedi ye-heat conduction ifakwa phakathi kwepuleti elibandayo elikhipha ukushisa kanye ne-heater chip ukuze kudluliselwe ukushisa okukhiqizwa yi-chip epuleti elibandayo elikhipha ukushisa, ngaleyo ndlela kunciphisa izinga lokushisa le-chip.Ukucindezeleka kokucindezela kuzokwenzeka lapho iphedi yokuqhuba ukushisa icindezelwa.Ukucindezeleka kokucindezela kuzokhula ngokunyuka kwenani lokucindezela.Uma ukhetha i-heat conduction pad, qaphela ukuthi ukucindezeleka kokucindezela kwephedi yokushisa ukushisa ngesikhathi sokucindezela akufanele kube mkhulu kunokucindezela okuphezulu okudingekayo kwe-chip yokushisa, ngaphandle kwalokho i-chip izolimala.

★ Kungani Khetha Us?

1. Ithimba lochwepheshe be-R&D

Ukwesekwa kokuhlolwa kohlelo lokusebenza kuqinisekisa ukuthi awusakhathazeki ngamathuluzi okuhlola amaningi.

2. Ukubambisana kokumaketha kwemikhiqizo

Imikhiqizo idayiswa emazweni amaningi emhlabeni jikelele.

3. Ukulawulwa kwekhwalithi okuqinile

4. Isikhathi sokulethwa esizinzile kanye nokulawulwa kwesikhathi sokulethwa kwe-oda okunengqondo.

Siyiqembu lochwepheshe, amalungu ethu anesipiliyoni seminyaka eminingi ekuhwebeni kwamazwe ngamazwe.Siyiqembu elincane, eligcwele ugqozi nokuqamba izinto ezintsha.Siyiqembu elizinikele.Sisebenzisa imikhiqizo efanelekayo ukuze sanelise amakhasimende futhi sizuze ukwethenjwa kwawo.Siyiqembu elinamaphupho.Iphupho lethu elivamile ukuhlinzeka amakhasimende ngemikhiqizo ethembeke kakhulu futhi sithuthukise ndawonye.Sithembe, siphumelele.

★ Izitifiketi

Izici Zemikhiqizo Eshisayo

-

Izici ze-Thermal Pad

1. I-conductivity enhle yokushisa: 1-15 W / mK.

2. Ubulukhuni obuphansi: Ubunzima busukela ku-Shoer00 10~80.

3. I-insulating kagesi.

4. Kulula ukuhlanganisa. -

Izici ze-Thermal Paste

1. Isigcwalisi segebe esihlukanisekayo esinezingxenye ezimbili, ingcina ewuketshezi.

2. I-Thermal conductivity: 1.2 ~ 4.0 W/mK

3. Ukufakwa kwamandla kagesi aphezulu, ukucindezela okuphezulu, ukumelana nokushisa okuhle.

4. Isicelo sokucindezelwa, singafinyelela ukusebenza okuzenzakalelayo. -

Izici ze-Thermal Grease

1. Ukuhlukaniswa kwamafutha aphansi (kubheke ku-0).

2. Uhlobo oluhlala isikhathi eside, ukwethembeka okuhle.

3. Ukumelana nesimo sezulu esinamandla (ukumelana nokushisa okuphezulu nokuphansi -40 ~ 150 ℃).

4. Ukumelana nomswakama, ukumelana ne-ozone, ukumelana nokuguga.